Biological Filtration 201 Chapter 3

Pressurized Filtration

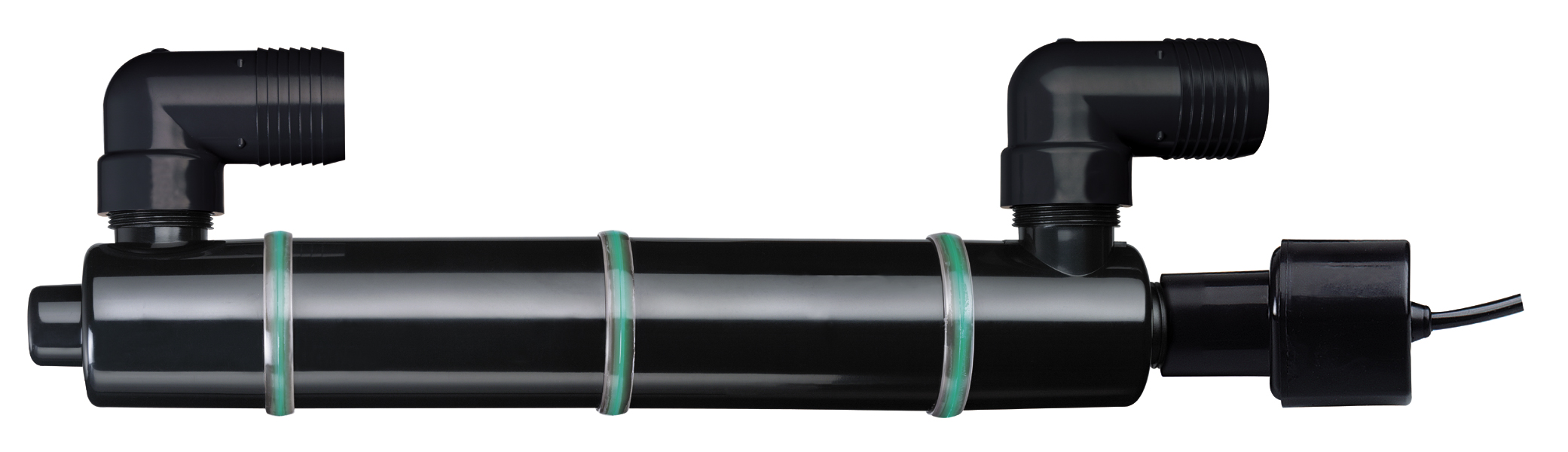

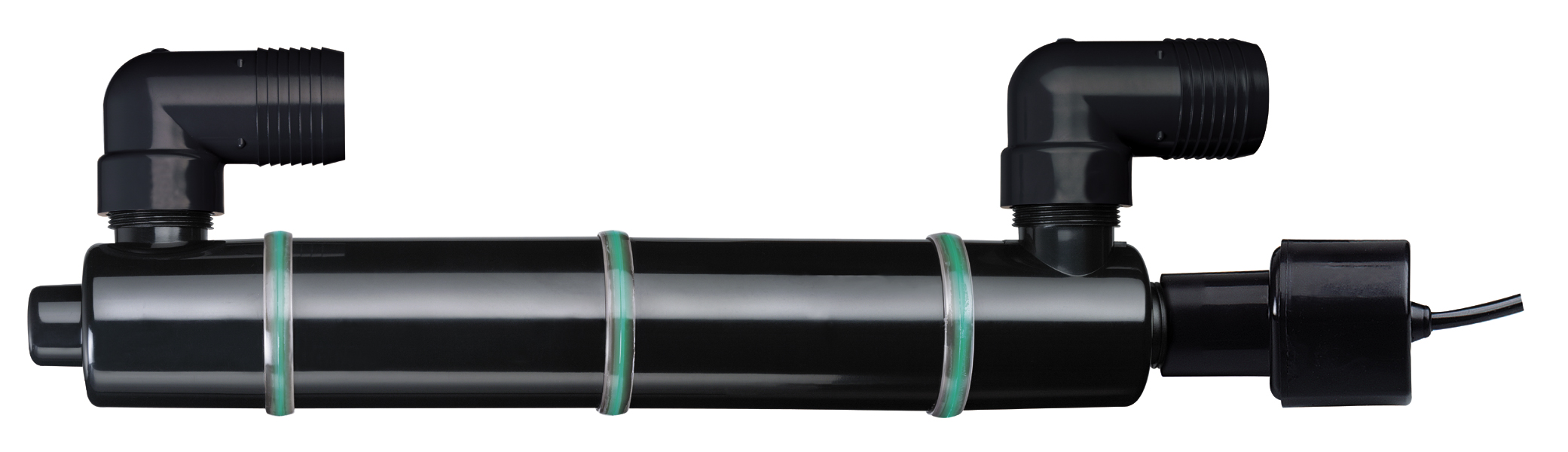

Both of the two preceding filters are called Gravity Filters because the water returns from the filter back to the pond via gravity, which means the filter has to be located at or above pond level. Pressurized Filters are sealed units with plumbed fittings in and out of the filter, so they can be located wherever the plumbing will reach, above or below water level, near or far from pump and pond, adding tremendous versatility. Larger pressurized filters for ponds look very much like the sand filters used for swimming pools, but beware! They are NOT the same animal!

Sand filters pass the relatively clear water from a swimming pool up through lots of coarse sand, which traps the few, tiny particles in poolwater and polishes the water to a sparkle. Pondwater is NOTHING like poolwater. Ponds are alive! Along with fish wastes and plant matter, bacterial colonies and algae mats, amoeba and paramecia, fungi and flagellates, daphnia and dragonflies and dove doo, there’s more gunk, junk and funk in a pond than in the most hideously neglected pool, and sand filters just can’t HANDLE the goop. Folks that try to use them soon find they have to be backwashed on a near-daily basis.

Also, sand filters are designed to be used with swimming pool pumps, capable of providing the great pressures needed to “fluff” hundreds of pound of wet sand during the backwash cycle to clear out debris and restore the filter to full function. High pressure means high head, by definition (remember, 1psi equals 2.31 feet of head?), but these high-head pumps are installed on swimming pools with zero vertical head - the water is taken from and returned to the same water level. High head pumps need a specific minimum head to work at, or they will “cavitate”, a condition that will eventually destroy both the motor and the impeller, so these pumps get the minimum head they need from friction head, the resistance inside restrictive plumbing. If forcing pumps to work hard through small diameter pipes sounds inefficient, that’s because it is, and all this pressure and restrictive plumbing leads to pretty high electric consumption, which is why no one runs their swimming pool filters 24/7 – they can’t afford to.

Pressurized filters that are designed from the ground up for pond use are sealed units, just like sand filters, and the best pressurized filters can be backwashed without having to open them, just like sand filters, but the way they remove debris is fundamentally different. Sand filters are mechanical filters, physically trapping debris in the tiny voids, or “interstitial spaces”, between sand grains until the spaces clog and the sand channels, letting water pass through large tunnels in the sand without getting filtered. Well-designed Pressurized Biofilters are biological filters first, and mechanical filters second; in fact, it takes some time before they filter anything at all! The reason why is they are generally filled with particulate filter media hundreds of times larger than sand grains. The relatively large pieces of plastic or ceramic are usually open shapes with lots of surface area, to allow aerated water to circulate freely through the media bed and to provide lots of real estate for bacteria to colonize - the more aerated water, the more surface area, the better the filter. This might sound contradictory – won’t open passages allow gunk to pass right through without getting trapped? Absolutely! In fact, when they’re first started up, these filters don’t do much of anything except to let some of the heavier particles settle out in the filter. The lighter particles will find their way through the filter media and back into the pond – but not for long.

All that aerated water creates a perfect environment for bacterial colonies to colonize, and colonize they will, as long as there’s plenty of oxygen and ammonia in the water. It will take a while. The “bugs” that convert ammonia to nitrate grow slowly, even under the optimal conditions found in these filters, but after 2 to 6 weeks, the bacteria will cover all those surfaces of the media with a sticky, slimy coating. Once this “biofilm” forms, any organic particles in the water moving through filter that collide with the media get trapped in the sticky film. Think of the old horror movie “The Blob”. As the bacterial slime digests the organic debris that it traps, it grows, the film thickens, the spaces in the media start to close as more and more debris gets trapped, so smaller and smaller particles get filtered out.

Pressurized Biological Filters may not start out filtering as well as a sand filter, but once the biological component kicks in, that bacteria not only removes ammonia, it creates a biofilm that mechanically filters out even the finest debris, eventually. You might say the clogged-er it gets, the finer it filters. Of course, that means it makes sense to wait as long as possible before backwashing to clean the media, so wait until the flow is visibly diminished, then backwash only enough to restore the flow. The LAST thing you want is to clean the media spotless, since it’s the sticky gunk on the media that’s actually doing the work, so you just need to knock off excess debris and dead bacteria. You also want to get the filter going again without delay, because drying the colonies out or starving them of oxygen will KILL them and you’ll have to wait another 2-6 weeks to get the cycle started again. This is a Big Deal. Without bacteria to remove ammonia, the fish in a well-established pond can suffocate in their own wastes very quickly. Kill the bacteria, kill the fish. Three things to remember:

Pressurized Biofilters need both aerated water and an ammonia source (fish wastes) to function;

They take time, even under the best conditions, to start up, or “cycle”, usually from 2-6 weeks;

Once established, the longer they run between cleaning/backwashing, the better they work.

Both of the two preceding filters are called Gravity Filters because the water returns from the filter back to the pond via gravity, which means the filter has to be located at or above pond level. Pressurized Filters are sealed units with plumbed fittings in and out of the filter, so they can be located wherever the plumbing will reach, above or below water level, near or far from pump and pond, adding tremendous versatility. Larger pressurized filters for ponds look very much like the sand filters used for swimming pools, but beware! They are NOT the same animal!

Sand filters pass the relatively clear water from a swimming pool up through lots of coarse sand, which traps the few, tiny particles in poolwater and polishes the water to a sparkle. Pondwater is NOTHING like poolwater. Ponds are alive! Along with fish wastes and plant matter, bacterial colonies and algae mats, amoeba and paramecia, fungi and flagellates, daphnia and dragonflies and dove doo, there’s more gunk, junk and funk in a pond than in the most hideously neglected pool, and sand filters just can’t HANDLE the goop. Folks that try to use them soon find they have to be backwashed on a near-daily basis.

Also, sand filters are designed to be used with swimming pool pumps, capable of providing the great pressures needed to “fluff” hundreds of pound of wet sand during the backwash cycle to clear out debris and restore the filter to full function. High pressure means high head, by definition (remember, 1psi equals 2.31 feet of head?), but these high-head pumps are installed on swimming pools with zero vertical head - the water is taken from and returned to the same water level. High head pumps need a specific minimum head to work at, or they will “cavitate”, a condition that will eventually destroy both the motor and the impeller, so these pumps get the minimum head they need from friction head, the resistance inside restrictive plumbing. If forcing pumps to work hard through small diameter pipes sounds inefficient, that’s because it is, and all this pressure and restrictive plumbing leads to pretty high electric consumption, which is why no one runs their swimming pool filters 24/7 – they can’t afford to.

Pressurized filters that are designed from the ground up for pond use are sealed units, just like sand filters, and the best pressurized filters can be backwashed without having to open them, just like sand filters, but the way they remove debris is fundamentally different. Sand filters are mechanical filters, physically trapping debris in the tiny voids, or “interstitial spaces”, between sand grains until the spaces clog and the sand channels, letting water pass through large tunnels in the sand without getting filtered. Well-designed Pressurized Biofilters are biological filters first, and mechanical filters second; in fact, it takes some time before they filter anything at all! The reason why is they are generally filled with particulate filter media hundreds of times larger than sand grains. The relatively large pieces of plastic or ceramic are usually open shapes with lots of surface area, to allow aerated water to circulate freely through the media bed and to provide lots of real estate for bacteria to colonize - the more aerated water, the more surface area, the better the filter. This might sound contradictory – won’t open passages allow gunk to pass right through without getting trapped? Absolutely! In fact, when they’re first started up, these filters don’t do much of anything except to let some of the heavier particles settle out in the filter. The lighter particles will find their way through the filter media and back into the pond – but not for long.

All that aerated water creates a perfect environment for bacterial colonies to colonize, and colonize they will, as long as there’s plenty of oxygen and ammonia in the water. It will take a while. The “bugs” that convert ammonia to nitrate grow slowly, even under the optimal conditions found in these filters, but after 2 to 6 weeks, the bacteria will cover all those surfaces of the media with a sticky, slimy coating. Once this “biofilm” forms, any organic particles in the water moving through filter that collide with the media get trapped in the sticky film. Think of the old horror movie “The Blob”. As the bacterial slime digests the organic debris that it traps, it grows, the film thickens, the spaces in the media start to close as more and more debris gets trapped, so smaller and smaller particles get filtered out.

Pressurized Biological Filters may not start out filtering as well as a sand filter, but once the biological component kicks in, that bacteria not only removes ammonia, it creates a biofilm that mechanically filters out even the finest debris, eventually. You might say the clogged-er it gets, the finer it filters. Of course, that means it makes sense to wait as long as possible before backwashing to clean the media, so wait until the flow is visibly diminished, then backwash only enough to restore the flow. The LAST thing you want is to clean the media spotless, since it’s the sticky gunk on the media that’s actually doing the work, so you just need to knock off excess debris and dead bacteria. You also want to get the filter going again without delay, because drying the colonies out or starving them of oxygen will KILL them and you’ll have to wait another 2-6 weeks to get the cycle started again. This is a Big Deal. Without bacteria to remove ammonia, the fish in a well-established pond can suffocate in their own wastes very quickly. Kill the bacteria, kill the fish. Three things to remember:

Pressurized Biofilters need both aerated water and an ammonia source (fish wastes) to function;

They take time, even under the best conditions, to start up, or “cycle”, usually from 2-6 weeks;

Once established, the longer they run between cleaning/backwashing, the better they work.